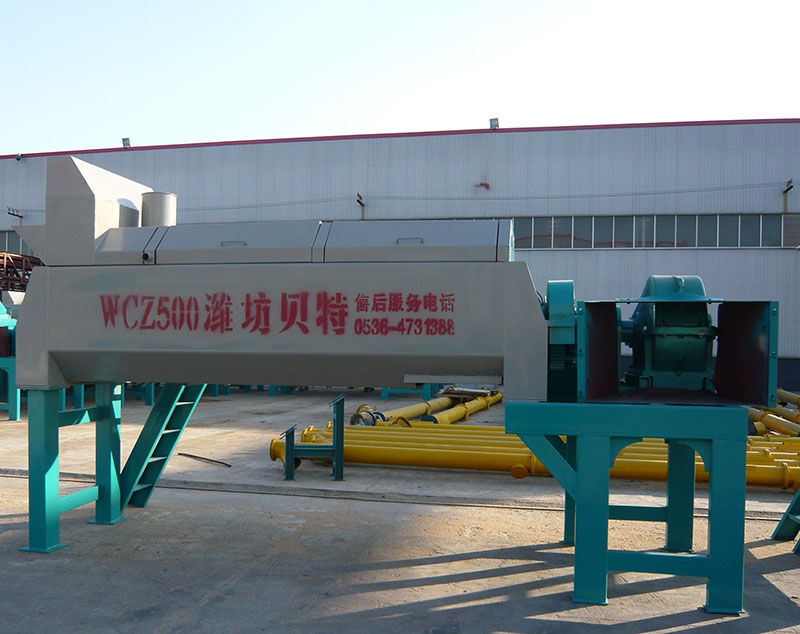

Production capacity : 400 t/h

Width of conveying belt :800mm

Storage bin : 8 m3

Discharging height : 3.7m

Total power : 100kw

High efficiency · Energy saving · Environmental protection · Superior Stability

1. Feeding system

l The aggregate hopper is equipped with oversize material screen.

l Vibrator keeps materials from jamming the gate or clinging to the bin walls.

l Aggregates are conveyed by frequency-controlled feeding belt, thus ensuring a high precision primary proportion.

l Dosing belt is supported with corrugated sidewall, which minimizes the waste of material. The scale is accurate to within ±2%.

2. Conveying system

l Motorized pulley has high conveying performance, low noise emission, and long service life.

l Two devices to prevent belt tracking problems: Tail tension screws can be adjusted manually to tighten or slack the belt. Belt sensor combined with pivot roller can automatically adjust belt.

l Belt cleaners work efficiently to keep belt clean.

3. Weighing system

Cement weighing

l Frequency-control cement scale is eco-friendly. It can minimize waste. The scale is accurate to within ±1%.

Water weighing

l Frequency-control water scale is easy to operate.

l Automatic frequency-control water scale is optional, which is accurate to within ±1%.

4. Dust removal system

Silo venting filter is designed with vertically mounted cartridge or bag-type filter. It works efficiently and is low-maintenance.

5. Mixing system

l Compared with traditional mixer, our twin-shaft continuous mixer is designed without liner plates, and thus has much smaller mixer body, lower wear costs and greater mixing efficiency.

l Mixer arms are easy to maintain and suffice many different mixing tasks.

l Two drive motors ensure a high level of constant mixing process. Motors are low-maintenance and have low noise emission.

l The mixer body is welded at automated production line, thus ensuring consistent quality and long service life.

6. Control system

Our control cabinet is user-friendly. Automatic, semi-automatic and manual controls are available. The control system also has such functions: recipe storage, automatic in-flight correction, parameter adjustment, scale calibration, automatic fault diagnosis, automatic alarm and sheet printing.

7. Service

Our plant is modular design. Installation, maintenance, and relocation are very convenient. Our service team is well trained to help customers with products purchase, operation, and maintenance.

Note: the parameters on this page are for reference only. The actual figures are subject to the actual configuration, and the interpretation right belongs to the manufacturer.