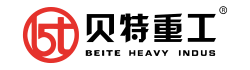

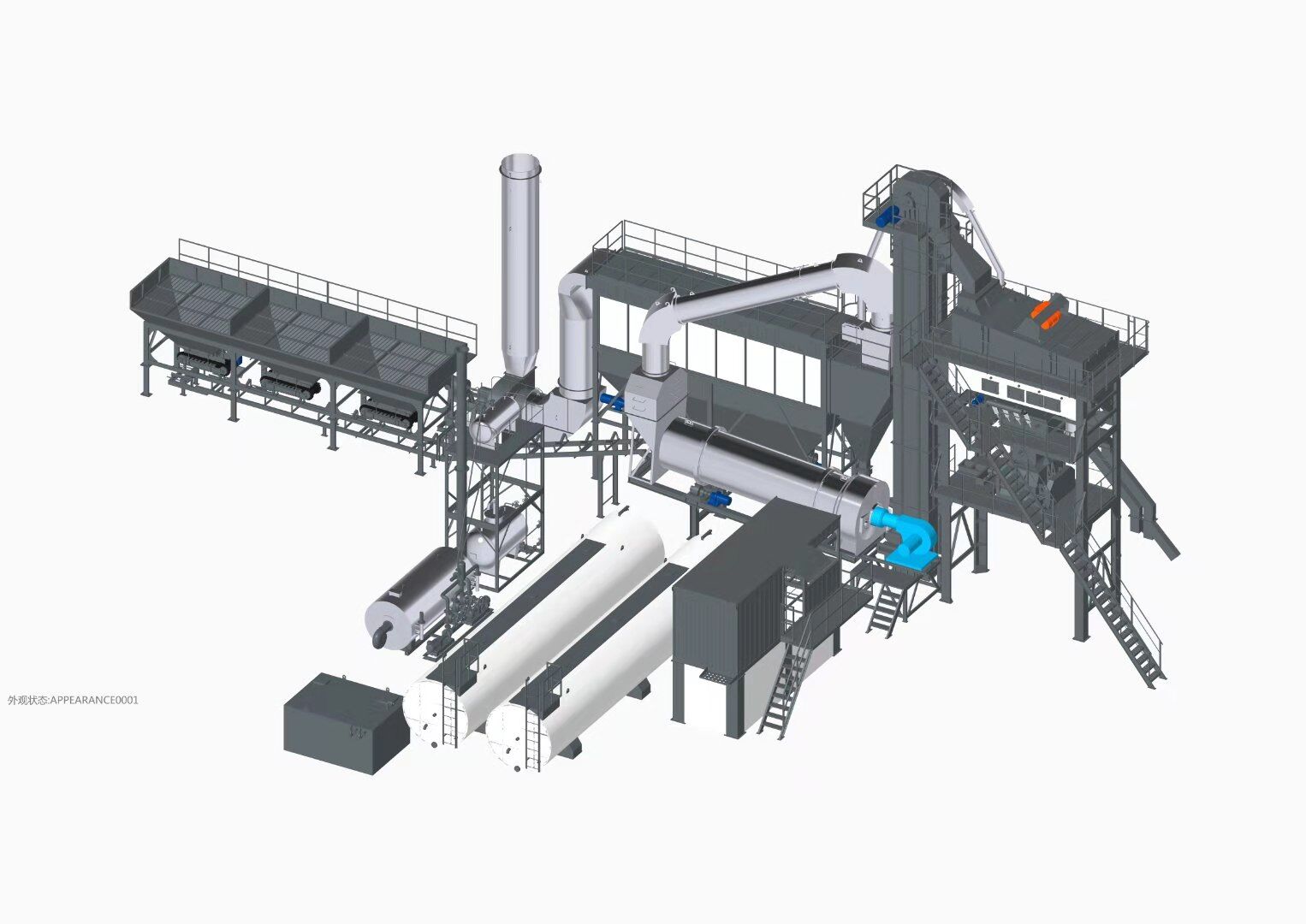

Asphalt mixing plant

Asphalt mixing plant is a complete set of equipment used for batch production, which can produce asphalt mixture, modified asphalt mixture, color asphalt mixture. It is widely used in the construction of highways, grade highways, municipal roads, airports, bridges, ports, water conservancy and hydropower projects.

Asphalt mixing plant is mainly composed of batching system, drying system, combustion system, hot lifting system, vibrating screen, hot storage bin, weighing and mixing system, bitumen supply system, filler supply system, dust collection system, finished product bin and control system.

Product features:

Our asphalt mixing equipment is modular design, with compact structure.The mixing pot has large mixing capacity. The blades and lining boards are made of nickel hard alloy, which makes their service life more than 100000 batches. The unique drop correction function and bitumen secondary weighing function ensures the measurement accuracy and bitumen-aggregate ratio accuracy.

High Efficiency

The asphalt mixing plant is modular design for easy installation, maintenance, relocation and transportation. The productivity is from 80t/h to 400 t/h.

High Stability

The equipment is controlled by industrial PC/PLC either automatically or semi-automatically or manually. It has the functions of formula input, automatic difference correction, bitumen-aggregate ratio dynamic tracking, automatic fault diagnosis, alarming and on-time printing.

Environment Protection

Inertia + pulse cleaning bag filter ensures strict environment protection standard. The flyash is recyclable. The noise and emission is all in compliance with national industry standard. The equipment is widely used in city and field construction.

Energy Saving

The total installation power is low. The fuel consumption is less than 6.5 kgs per ton of asphalt mixture. It is very economic for the customers.

LB Series Asphalt Mixing Plant Parameters:

Note: the parameters on this page are for reference only. The actual figures are subject to the actual configuration, and the interpretation right belongs to the manufacturer.

LB800 Asphalt mixing plant

LB800 Asphalt mixing plant LB1000 Asphalt mixing plant

LB1000 Asphalt mixing plant LB1500 Asphalt mixing plant

LB1500 Asphalt mixing plant LB2000 Asphalt mixing plant

LB2000 Asphalt mixing plant LB2500 Asphalt mixing plant

LB2500 Asphalt mixing plant LB3000 Asphalt mixing plant

LB3000 Asphalt mixing plant LB4000 Asphalt mixing plant

LB4000 Asphalt mixing plant LB5000 Asphalt mixing plant

LB5000 Asphalt mixing plant Mixing tower

Mixing tower Dust collection system

Dust collection system Control system

Control system Heating and drying system

Heating and drying system Batching system

Batching system